Understanding Automotive Wiring Systems

Automotive wiring systems are essential to the functioning of vehicles, providing the electrical pathways necessary for various systems to operate. These intricate systems comprise multiple components, including sensors, lighting, and entertainment applications, all controlled through an organized network of wires and connectors. To gain a comprehensive understanding of these systems, it is crucial to explore specific elements such as automotive wiring schematics, wiring symbols, and the role of fuses in electrical systems. For further detailed resources, including wiring diagrams and fuse specifications, you can visit https://bezpieczniki24.pl.

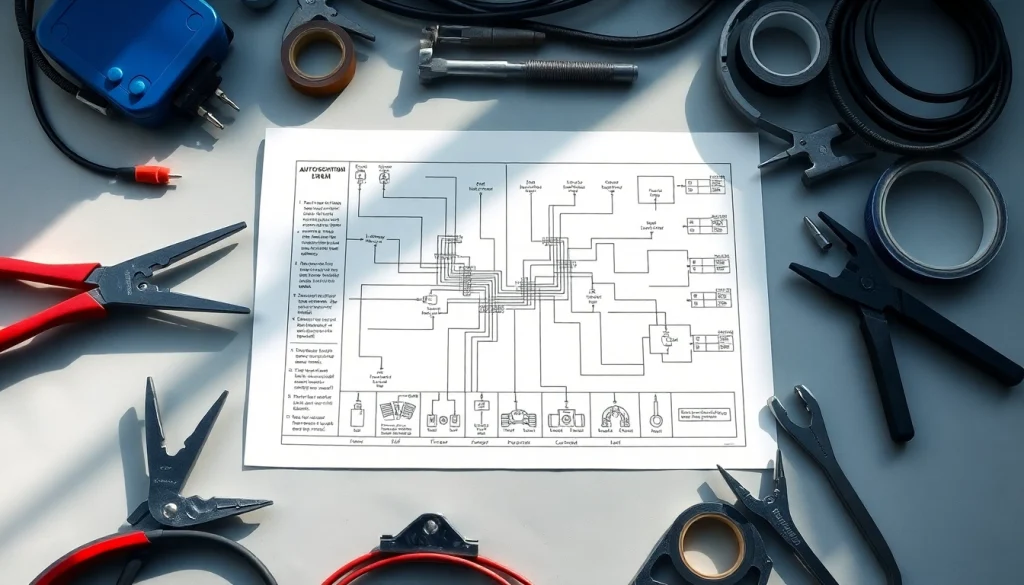

What Are Automotive Wiring Schematics?

Automotive wiring schematics are visual representations that illustrate how electrical circuits within a vehicle are interconnected. These diagrams serve as critical resources for understanding the layout, conductors, and components of a vehicle’s electrical system. They typically include information on wiring configurations, fuse locations, and the operation of specific devices.

The significance of schematics lies in their ability to guide technicians during diagnostics and repairs. Recognizing the arrangement of various wires can significantly reduce troubleshooting time. Each schematic is tailored to a specific vehicle model, highlighting that different cars or trucks may have varied configurations even for similar components.

Common Wiring Symbols Explained

In wiring schematics, standardized symbols are used to convey information succinctly. Some common symbols include:

- Power Source: Typically represented as a battery symbol, indicating where electrical power originates.

- Ground: Denoted as a tree-like symbol, indicating a connection to the vehicle’s chassis.

- Switch: Illustrated with a break in the line, showing where a circuit is open or closed.

- Fuse: Shown as a rectangle, indicating components that provide overload protection.

Familiarity with these symbols is vital for both novice and experienced technicians, allowing quick interpretation of wiring diagrams and more efficient repairs.

The Role of Fuses in Electrical Systems

Fuses are crucial safety components in automotive electrical systems. Their primary function is to protect sensitive circuits from overloads caused by short circuits or excessive current. When the electrical flow exceeds the fuse’s rated capacity, the fuse “blows,” interrupting the circuit’s power supply to prevent damage to wiring or components.

Understanding the specific role of each fuse can help technicians quickly diagnose electrical problems. For instance, if a particular system fails, checking the related fuse can often provide immediate insight into the issue. Fuses come in various sizes and ratings, catering to different electrical demands within a vehicle.

Types of Automotive Fuses

Automotive fuses come in various types, and understanding the differences can help you make informed decisions when maintaining or repairing a vehicle’s electrical system. The most common types of fuses include blade fuses, glass fuses, and box fuses.

Blade Fuses vs. Glass Fuses

Blade fuses are among the most widely used fuses in contemporary vehicles. They feature two metal prongs that fit into a rectangular plastic casing, allowing for easy replacement. Their design facilitates quick identification of blown fuses, as they are available in various colors corresponding to their amperage ratings.

In contrast, glass fuses are typically found in older vehicles and are encased in a transparent glass tube. While they serve the same protective function, they can be more challenging to diagnose. Technicians must physically inspect these fuses to determine if they have blown, which can be less convenient than checking blade fuses.

Box Fuses and Their Applications

Box fuses, often mounted in a fuse box located within the vehicle, are designed to handle substantial electrical loads. These fusible links are commonly associated with high-power systems, including starter motors and headlights, due to their higher amperage ratings. Proper identification and maintenance of box fuses are critical, as failure can lead to significant electrical issues.

Choosing the Right Fuse for Your Vehicle

Selecting the correct fuse type and rating is essential for both safety and performance. When replacing a fuse, ensure that the amperage rating matches the original to prevent potential electrical failures. Always consult the vehicle’s owner’s manual or a qualified auto technician if there is uncertainty regarding which fuse to use.

Diagnosing Electrical Issues

Electrical problems in vehicles can be perplexing, but a systematic approach can help identify the issues efficiently. By understanding common symptoms and diagnostics tools, technicians can streamline the troubleshooting process.

How to Identify Fuse Problems

Often, fuse problems manifest as a sudden failure of electrical components. If multiple systems powered by the same circuit cease functioning, it is likely that the fuse has blown. An initial examination of the fuse can confirm this; a blown fuse will show visual signs of damage, such as a melted wire or discoloration inside the casing.

Common Symptoms of Electrical Failures

Some common indicators of electrical failures include:

- Failure of specific lights or dashboard indicators

- Audible warning systems not functioning

- Electronic stability control systems malfunctioning

- Unresponsive infotainment systems

Any of these symptoms can point towards electrical faults, and technicians should utilize wiring schematics to identify potential culprits.

Using a Multimeter for Diagnostic Testing

A multimeter is an invaluable tool for diagnosing electrical issues. This device can measure voltage, current, and resistance, helping technicians pinpoint problems within automotive circuits.

To use a multimeter effectively:

- Set the multimeter: Adjust the settings based on what you need to test (voltage, current, or resistance).

- Test the circuit: Connect the probes to the respective terminals while the circuit is powered on, and observe the readings.

- Interpret results: Compare the readings against the specifications in the wiring diagram to determine if components are operating within their nominal ranges.

Utilizing a multimeter allows for precise diagnostics that can lead to efficient repairs.

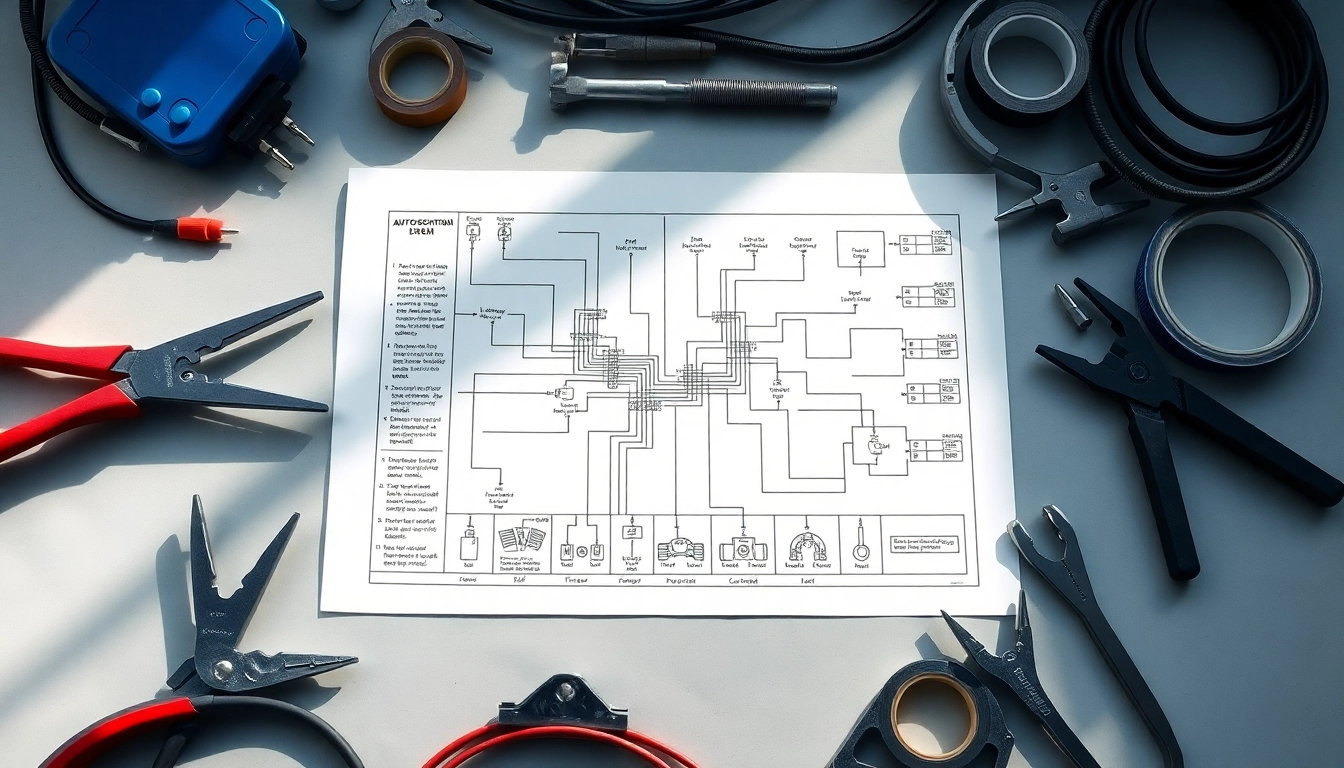

Step-by-Step Fuse Replacement Guide

Replacing a blown fuse is a manageable task that can save both time and money. This step-by-step guide outlines the process to ensure it is done safely and correctly.

Preparing for Fuse Replacement

Before beginning, gather the necessary tools, including a pair of pliers (or specialized fuse pullers), the replacement fuse matching the amperage, and safety gloves. Ensure that the vehicle is turned off to prevent any electrical hazards during the replacement process.

Executing a Safe Fuse Change

To safely replace the fuse, follow these steps:

- Locate the fuse box, which can often be found under the dashboard or in the engine compartment.

- Refer to the vehicle’s manual to find the specific fuse in question and its corresponding amperage rating.

- Use pliers to carefully pull out the blown fuse, taking care not to damage neighboring fuses or components.

- Insert the replacement fuse, ensuring it is securely positioned.

Post-Replacement Testing and Maintenance

After replacing the fuse, turn on the vehicle to test the functionality of the affected system. If the new fuse operates correctly, ensure that the fuse box cover is replaced. Regular inspection of fuses is good practice to anticipate potential issues before they escalate.

Advanced Wiring Techniques

For those comfortable with basic automotive wiring, there are advanced techniques that can enhance performance and reliability. These methods involve modifications and integrations that improve vehicle functionality.

Modifying Wiring for Enhanced Performance

Performance modifications can improve efficiency and responsiveness. These modifications might include upgrading wiring harnesses to a thicker gauge for better current flow, which can reduce resistance and improve electrical delivery to components. Such upgrades are vital for vehicles that spend significant time under high load or in performance applications.

Integrating New Electrical Components

When adding new electrical components, such as aftermarket stereos, lighting options, or enhanced engine management systems, wiring integration becomes crucial. It is essential to ensure that the new components match the existing electrical system’s specifications and that they are installed with appropriate fuses and wiring ratings.

Ensuring Safety and Compliance in Wiring Modifications

All modifications must adhere to safety standards to prevent electrical fires or system failures. This involves using correctly rated components, ensuring connections are secure, and insulating wires properly. Compliance checks can be beneficial, especially for vehicles up for regular inspections.